Tipo di pagamento:L/C,T/T,D/P,Paypal

Incoterm:FOB,CFR,CIF,EXW,FCA,DDU,DDP,DEQ,CIP,CPT

Quantità di ordine minimo:100 Kilogram

Trasporti:Ocean,Land,Air

Porta:Shanghai,Qingdao,Shenzhen

$1-9.9 /Kilogram

Modello: Wear Plate-HP700

marchio: Piastra HP, saldatura HP

Standard: ASTM, DIN, GB, JIS, AiSi, bs

Specie: Lamiera di acciaio

Processo Produttivo: Laminati a freddo

Trattamento Della Superficie: Rivestito

Applicazione: Flangia Piastra

Acciaio Speciale: Acciaio resistente all'usura, Piastra in acciaio ad alta resistenza

Tolleranza: ± 1%

Categoria: Lamiera di acciaio laminata a freddo, Lamiera di acciaio rivestita di colore, Lamiera di acciaio, Lamiera di acciaio zincata a caldo, Piastra a bassa lega, Lamiera di acciaio laminata a caldo

Servizio Di Elaborazione: Flessione, Saldatura, Decoiling, Taglio, Punzonatura

Luogo D'origine: Cina

Standard Size 1: 4.92' X 9.84' Or 1500 X 3000mm

Standard Size 2: 4.59' X 9.84' Or 1400 X 2900mm

Standard Size 3: 3.94' X 9.51' Or 1200 X 2400mm

Standard Size 4: 7.22' X 9.84' Or 2200 X 3000mm

Standard Size 5: 3.28' X 9.84' Or 1000 X 3000mm

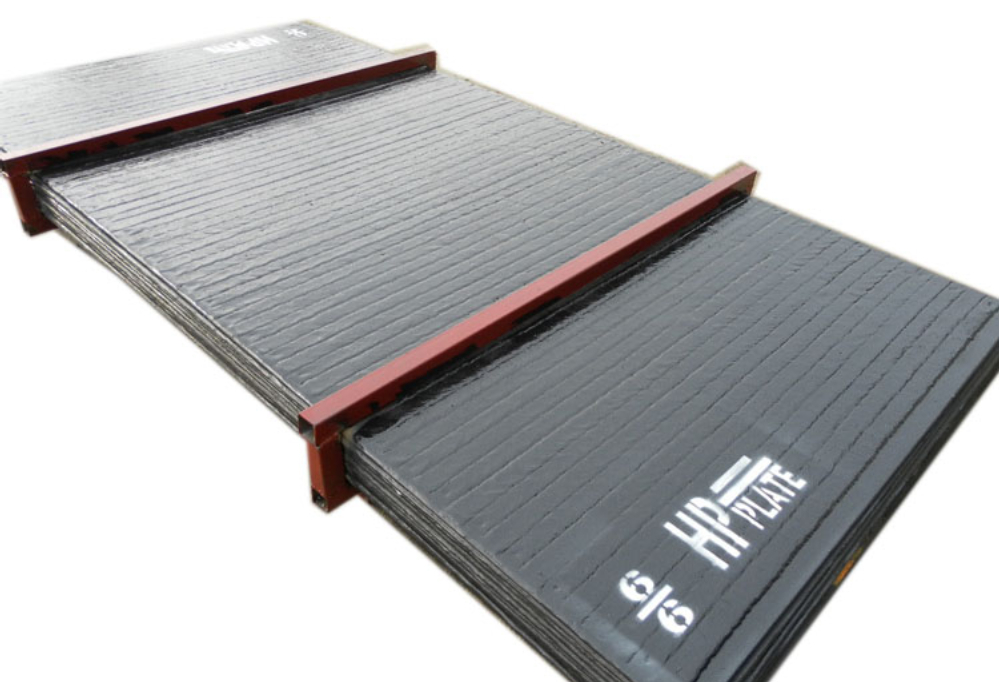

Standard Thickness 1: 2on3, 2on4, 3on3, 3on5, 4on6, 6on6

Standard Thickness 2: 7on8, 8on8, 9on10, 10on10, 12on12,10on20

Standard Thickness 3: 9on8, 12on8, 15on10,17on12, 20on12, 25on10

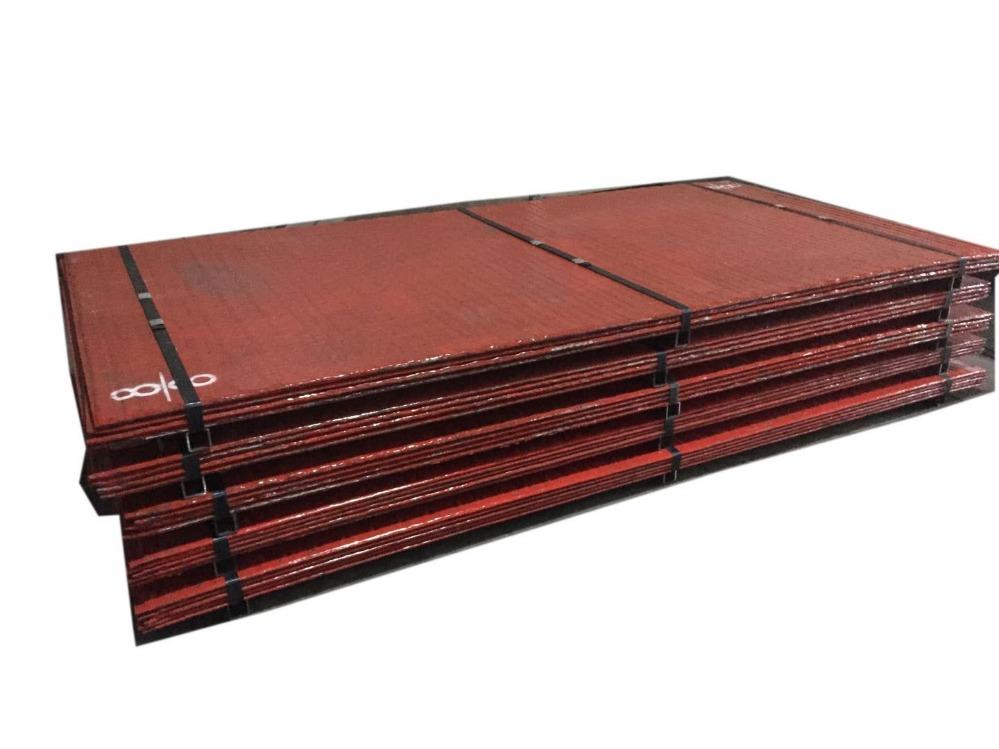

Pacchetto: Blocco per grafici in acciaio e cintura in acciaio fissata

produttività: 5000 tons

Trasporti: Ocean,Land,Air

Luogo di origine: Cina

Supportare: 50,000㎡ wear plate per year

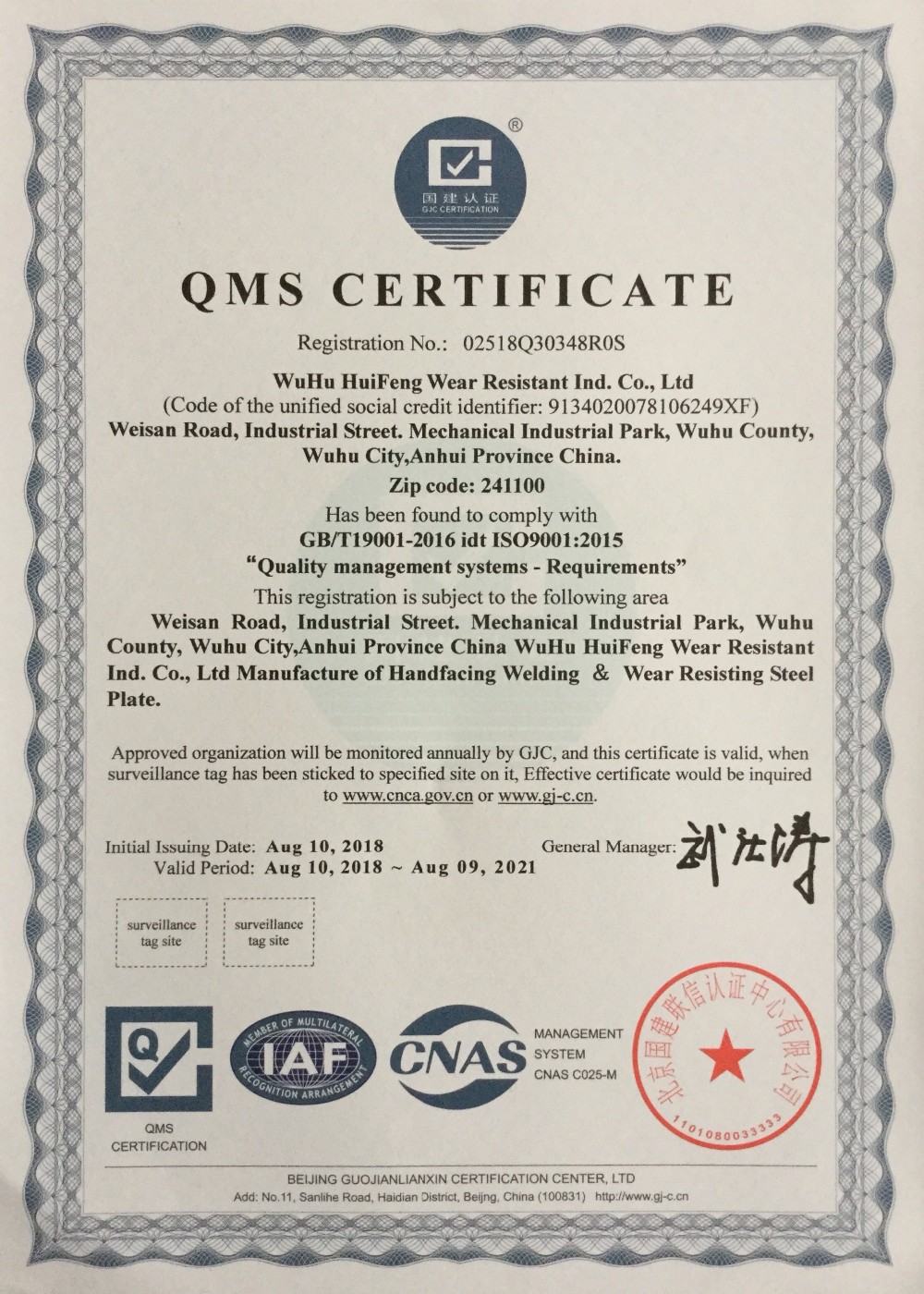

Certificati : ISO9001: 2015

Codice SA: 72109000000

Porta: Shanghai,Qingdao,Shenzhen

Tipo di pagamento: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,DDU,DDP,DEQ,CIP,CPT

Wear Plate is kind of Chromium Carbide Overlay Steel consisting of mild steel as base and Chromium Carbide Overlayer.

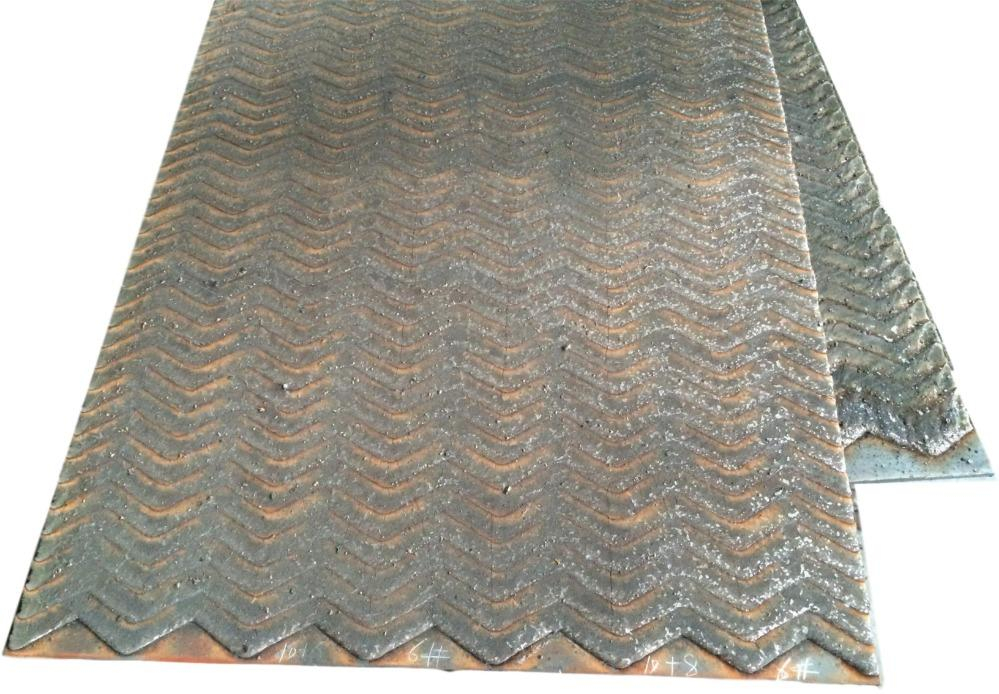

The smooth surface of a Chromium Carbide Wear Plate can reduce the coefficient of friction and thus reduce wear. At the same time, it can also reduce material hang-up in "sticky" applications (iron ore mines). The friction coefficient of the polished HP Clad Plate is 35-45%lower than other wear resistant products. In "sticky" applications or in cold areas, the probability of material hang-up is reduced by65-75%

A crack-free smooth surface also has a natural advantage when there is impact and wear. An uneven wear surface can increase the wear rate through micro-turbulence and impact.

HP Abrasion Resistant Steel Plate have been widely used in the fields of mining, quarrying, cement, metallurgy, thermal power, engineering and mining machinery.

Quick View On P roduct

1. Product Name: HP Chromium Carbide Overlay Wear Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

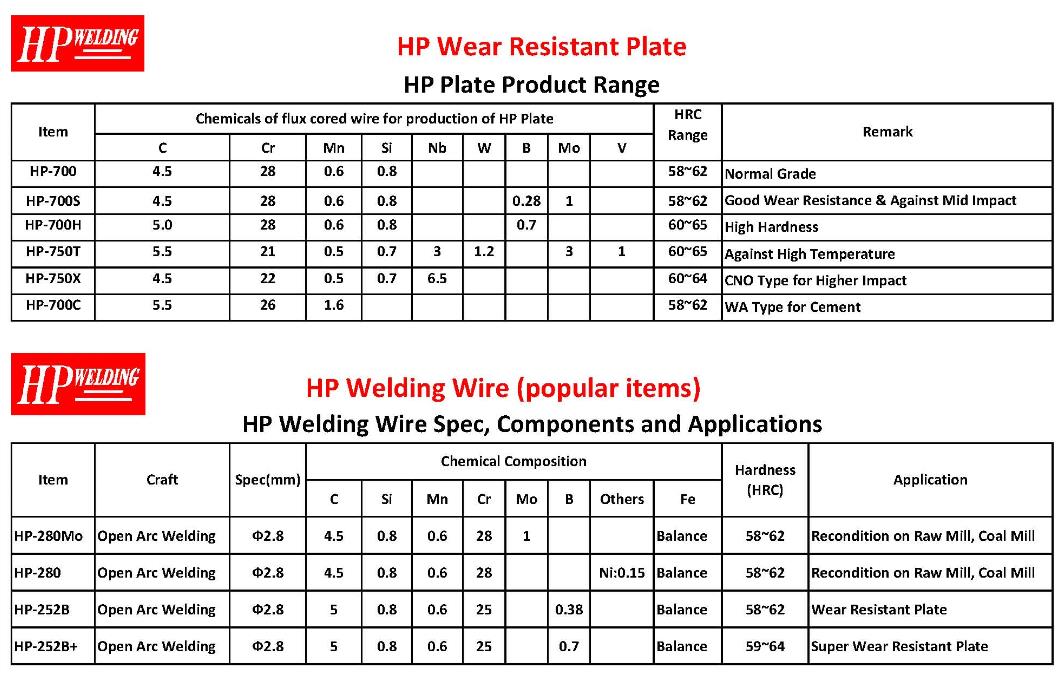

3. Grade: HP700, HP700S, HP750X, HP750P

4. Standard Size: 1200*2400mm; 1500*3000mm; 2200*3000mm or customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

6. Applications: Cement Industry , Steel Mill, Mining Site, Coal Mine

Chemical Industry, Power Generation & Others

7. Certification: ISO9001, SGS, CTI, ROHS

Standard Specifications of HP Wear Plate :

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

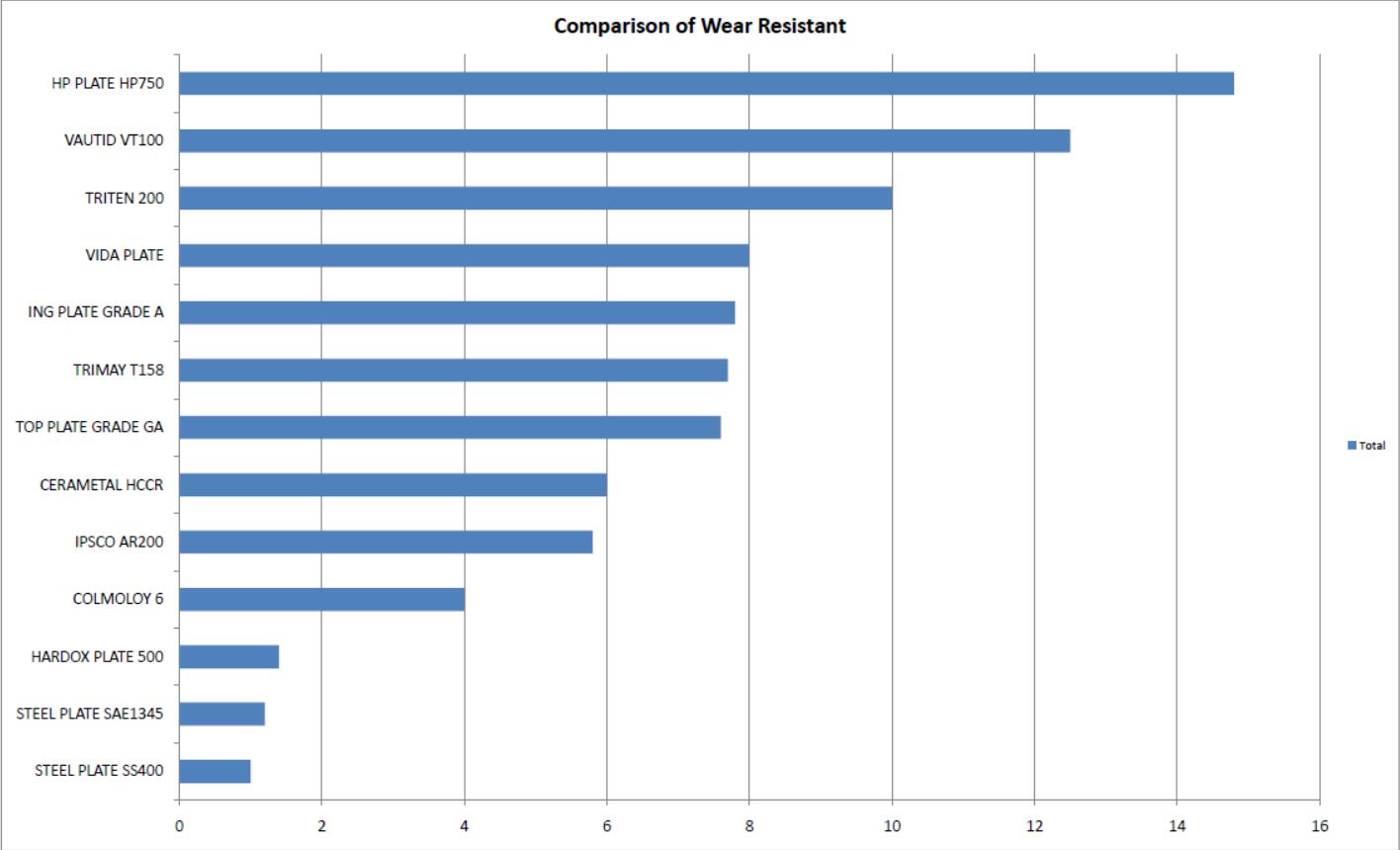

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Risposta: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.